Kawa introduces now premium and state of the art metal forming machinery both for capital good and consumer durable industries. In metal forming section press brake now become an important production equipment, Which has wide application both in capital and consumer goods sector’s. CNC controllers have increased its utility by way of productivity.

Download Technical Data- Design of KE press brake is based on S-R-B (synchronized bed reference) principle with Y - Y2 control.

- Rigidly welded, stress relieved frame ensures minimum deflection even under maximum load.

- Cylinders from high quality forged steel are precisely honed. Pistons are hard chromed for longer life.

- Rigid and accurate guiding of pressing beam to achieve desired beam-tilt.

- Full electronic synchronization with proportional valve technology assures constant monitoring and correction of beam parallelism through CNC system.

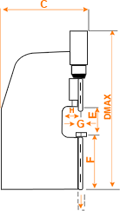

- Stroke depth measurement through high precision linear glass scales up to 0.021 mm.

- Precise press beam depth mechanism enables desired bending accuracy and repeatability even over longer use.

- Off centre bending without any damage to guiding system.

- Controller and backguage options available.

- Safety regulations as per the industrial norms.

- N. C. Control for complete setting and operation's

- Only NC. Back gauge

- Electronic hand safety devive

- Degree protector on table

- Ball transfer unit on table

- Extra long squaring arm

- Foundation Bolts

- Color Scream as Per Your STD.

- Anti Deflection System

- Hydraulic Tool Clamping

- Hydraulic Sheet Follower System

- Laser Based Bend Measuring System

- Design of KE press brake is based on S-R-B (synchronized bed reference) principle with Y - Y2 control.

- Rigidly welded, stress relieved frame ensures minimum deflection even under maximum load.

- Cylinders from high quality forged steel are precisely honed. Pistons are hard chromed for longer life.

- Rigid and accurate guiding of pressing beam to achieve desired beam-tilt.

- Full electronic synchronization with proportional valve technology assures constant monitoring and correction of beam parallelism through CNC system.

- Stroke depth measurement through high precision linear glass scales up to 0.021 mm.

- Precise press beam depth mechanism enables desired bending accuracy and repeatability even over longer use.

- Off centre bending without any damage to guiding system.

- Controller and backguage options available.

- Safety regulations as per the industrial norms.

Other Products

Believing in the Motto of Quality over Quantity

Shailesh Group has firmly believed in delivering quality power press products

all over the world in order to become a pioneer in the field of power press manufacturing.