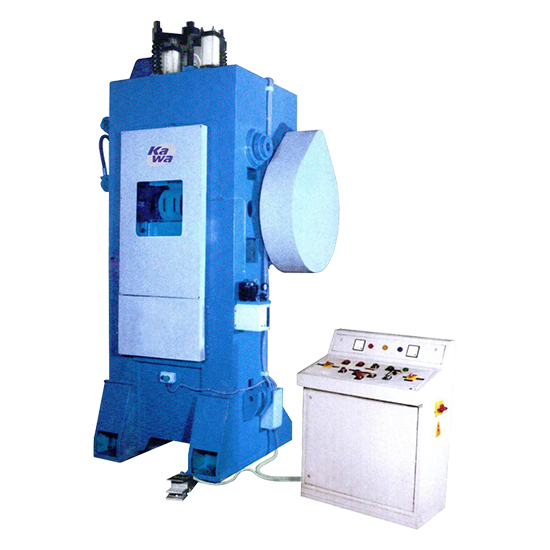

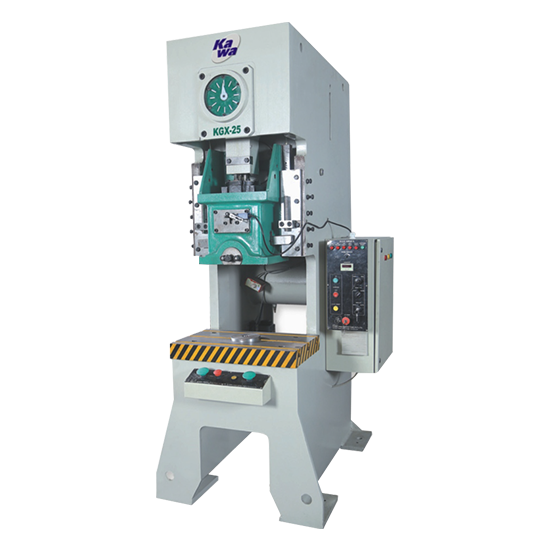

KGX Series

“Kawa” introduces state of the art Cross shaft presses having 10 tons to 250 tons capacity having rigid frame construction incorporating several std/optional features for optimum productivity like pneumatic clutch, brake unit, pneumatic die cushion, stroke counters, hydraulic overload safety device, electronic operator safety device hydraulic tool clamping systems, quick die unloading systems, Centralised automatic lubrication etc. Press automation can also be done with the installation of de-coilers, straightness, feeders, choppers etc. Special executions are also possible to meet individual production requirements.

Download Technical Data

- Reduced noise and vibrations.

- Minimum frame gapping, low, angular deflection.

- High rigidity frame and bolster.

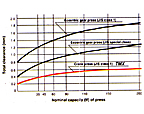

- High precision forming for longer dielife.

- Hi-Torque pneumatically operated single disk combined clutch and brake unit.

- Gear transmission runs in oil bath.

- Wide slide and bolster area.

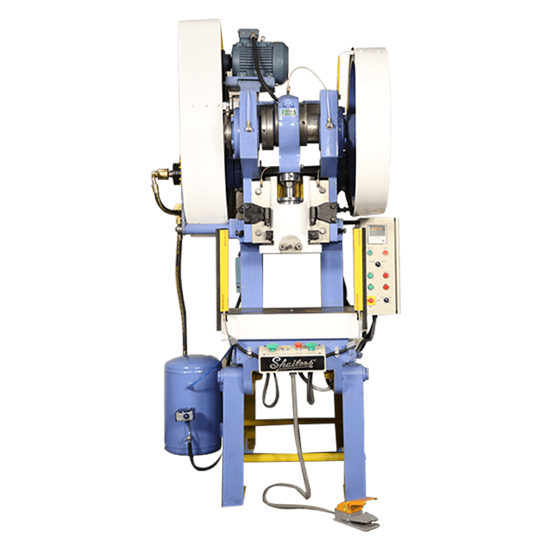

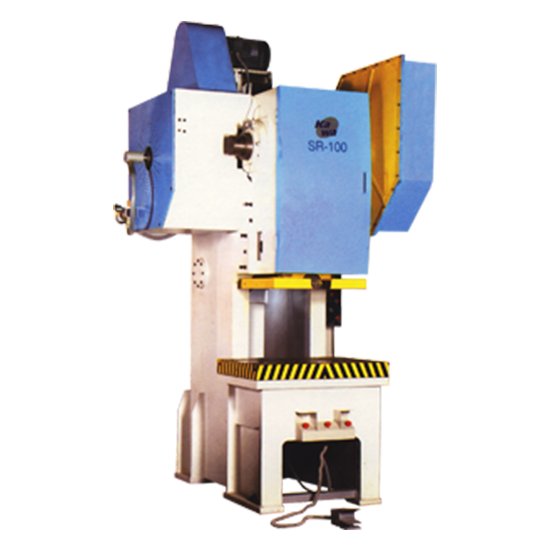

Other Products

Believing in the Motto of Quality over Quantity

Shailesh Group has firmly believed in delivering quality power press products

all over the world in order to become a pioneer in the field of power press manufacturing.